+ Cooling Device

Details

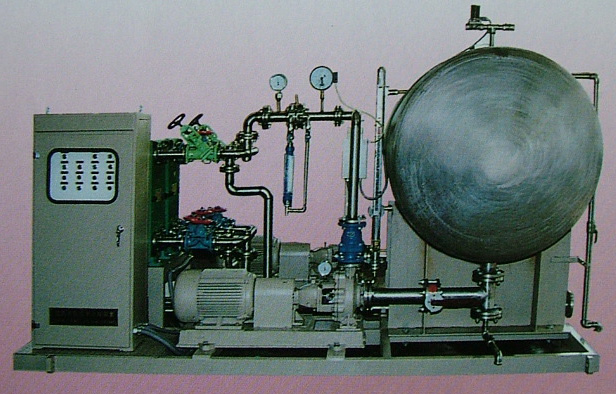

SL series demineralized water cooling device

Product Structure and Functions

Demineralized water pipelines are match designed with “The Equipment for Sampling Water & Steam” to form a close-cycle system. Demineralized water enters the cooler of sampling equipment form Coolong Device to cool sample water and then returns to demineralized water tank after being heated. The heated demineralized water will be pumped from water tank into the heat exchanger of Cooling Device. On one side of heat exchange is demineralized water; on another side is industrial water. Temperature of demineralized water will reduce after passing heat exchanger to meet working requirements of Equipment. Then, demineralized water will enter sampling equipment, continuously recycling.

Two water pumps, standby for each other, are provide for Cooling Device to ensure discontinuous output of demineralized water. When the pump in operation goes wrong or cannot meet water supply requirements of Equipment, that is, pressure of demineralized water in Equipment is less than 0.2Mpa, it will stop working automatically. And at the same time another standby pump will come into operation automatically to meet demineralized water supply requirements of Equipment.

Magnetic float level gauge is provided for demineralized water tank to show water level and give an alarm for toplimit or bottom-limit level, insuring that there is enough water in demineralized water tank. When water level is lower than bottom-limit, the gauge will send alarm signal and open solenoid value automatically to fill water at the same time . When water level reaches top-limit, the gauge will send signal to close solenoid value.

For pipes through which industrial cooling water enter heat exchanger as well as pipes through which demineralized water enter water pumps, filters are provided by Cooling Device for them to protect water pumps and heat exchanger.

Also flowmeters are set for demineralized water pipelines of Cooling Device to observe change of flow rate and adjust the fiow rate to meet working needs.

Product Characteristic

All components are laid on a pedestal, so the Cooling Device has compact structure and small overall size. Water pumps are separately located on both sides and there is enough space left for overhaul and maintenance, The operating pump will not affect maintenance of the wrong pump.

Heat exchanger is located on frame flat roof to make installations & maintenances not be affected by component s around.

Demineralized water tank is laid on the pedestal, reliable and stable.

Electric control cabinet is located at the corner of the pedestal, easily operated and maintained with control surface facing outside.

Pipes of demineralized water, flanges and filters adopt stainless steel material. Stainless steel valves or rubber lined valves are adopted.

Cooling course of demineralized water is a completely close cycle and form a separate system itself, so the Cooling Device eliminates interfere of external system entirely and insures the working pressure and temperature of demineralized water and then ensures that Equipment works safely and reliably.

Components:

Water pumps

Heat exchanger

Electric control cabinet

Components:

Water pumps

Heat exchanger

Electric control cabinet